Just picked up this champion 400 blower from a fellow guild of metalsmiths member. It looks pretty crunchy but it works fantastic. It is missing the stand but that shouldn’t bee too much of a problem. Plan on opening it up, cleaning and oiling it this weekend. Feeling excited that I’m close to getting the coal forge fired up!

Very nice!

Great looking blower! Went hand cranked, eh? I think that is a great feel to it, something about powering it without electrical means makes it feel… better. Also, you won’t forget a fan switch on and let that fire get too hot

Can’t wait to see the stand you make for this guy

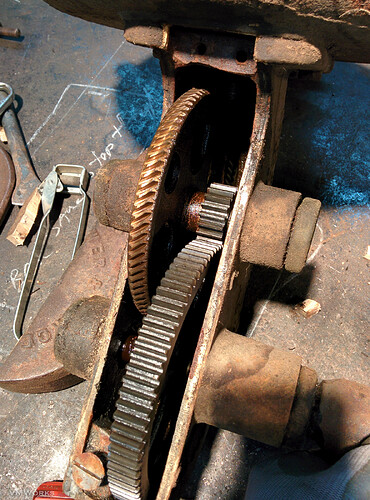

I was thinking of buying a electric powered blower but I started thinking about where and when I was going to use the forge and the hand cranked unit made much more sense. Plus it’s satisfying to run the forge and eliminate the humming of electric motors. I’m going to keep this outside with the forge so the plan is to clean it up and add a new coat of paint. I opened it up and the gears look perfect. The oil was pretty dry and more than likely original but it was enough to keep everything inside from rusting so I’m pretty happy. It does need a new handle so I need to figure that out still.

I’m a wood turner as well, if you want to send it by post I can make a replica handle…pm me if you can get the wood off. Some are riveted on handle studs,

Chadwick…wow I’m stunned by that generous offer! I’ll share a few photos so you can see what I’m working with. I was able to remove the handle after a little tough love and see what remains. It looks like the wood had two metal bushings that were fixed to the wood and would spin on the metal shaft. With the current handle they were pretty loose in there so it was really just wood spinning on metal and it made the hole in the handle oversized.

What do you think? I’m no wood turner so I don’t know how difficult it would be to reproduce this part.

I’m also rethinking cleaning up the blower. The rust is growing on me. I’m contemplating leaving it as is but giving it a nice wax finish to keep it from degrading any further. What do you guys think?

-Jeff

Yeah, that’s not bad, maybe two hours of work, taking into account that it needs to be bored from both ways and all for the bushings. I have cherry, white oak, red oak, walnut, cocobolo, and I can get hickory, maple or, mahogany from an Amish carpenter freind of mine.

Cherry, maple, hickory,or oak, are likely closer to original as that was made here in PA, and we are drowning in those trees! Walnut or cocobolo would be a fancy choice! And mahogany is a softer wood that would look great but dent and wear quickly.

Think about what you like, if you want to send me the handle and the stud,that way I can get it just right. We’ll swap addresses and you can include postage so I can send it back.

Oh, and think about ergonomics, would you feel more comfortable with a larger diameter handle ect. So that you can crank it for longer!

Sent you a pm this morning

One thing I gotta know…what’s the meaning of Javos?