How do you keep an anvil quiet? I’ve heard of magnets on the anvil, where should they be attached?

I thought the magnet some folks had was for determining when steel was at non magnetic temps? Or maybe they are dual purpose magnets for noise / temp? I do I see lots of smiths use chains to help cut down on the noise.

I have seen several references about setting your anvil on a bed or tray of sand. Apparently this is fairly popular in Europe

I have a little 90-95 lbs Trenton that I use for cutting (I almost always keep the hardy in it). When working steel on the top, it has a pretty significant ring. I wrapped a chain around the waist and that helped a little bit, but I was just thinking about how quiet that anvil seems, over the last few sessions.

Then I just now remembered I have a pretty strong magnet attached to one side. After reading one of Javos Ironworks posts, I’ll have to check it with and without the magnet and see if that is what brought the volume of the ring down.

One thing I know for sure, is that quietest anvil I have ever seen used was wedged into a good steel stand that had 4 square tube legs that were filled with oil and sand. Those legs were then set in concrete with three bags of concrete anchoring each leg. It is a true beast of a stand.

I’d like to see that stand, Tulsa! Don’t suppose you got any shots of it about?

I have a big ol’ Hay Budden (400+). Rings like a church bell when struck.

I do the magnet trick and it works quite well, actually! I put two under the heel and one under the horn when I am not using it. They are Neodymium magnets, hold really strong so they don’t drop off.

Additionally, I wrap chain around it and have it also have silicone caulk between the anvil and stand.

Tulsa - I want to see that anvil mounted in concrete, sounds like a beast!

I bought a anvil last year and built a three legged stand. I has some 2" x3" solid material from a previous project laying around so I used that for the legs thinking the more mass the better. I then used a tube of silicone between the base and and the stand. I’m not sure if it’s the mass or the silicone but the ring is pretty minimal with my setup.

I don’t have any pictures of it right now, but next time I go out there (It’s at Ed Brazeal’s house), I’ll get a picture. I should probably add that a well-secured anvil is one of the biggest points Ed and Brian consider to be crucial as preparing a properly set up smithy. The anvil is big (between 250-350 lbs) and it has absolutely no ring. I’ve heard Ed say that it is extremely important to moving steel efficiently. They use no chains or magnets.

That’s a really nice stand, by the way, and very similar to Ed’s. His point is for a person to consider that if the anvil is solidly mounted to a stand that is solidly mounted to the earth, it fully maximizes its mass, as the stand can be considered to have useful weight to add to the anvil.

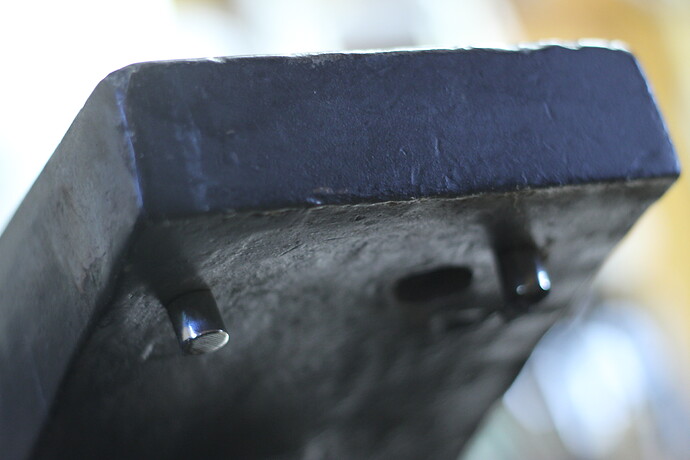

Here are a few shots of mine - 400+ Hay Budden on a 217lb factory stand. I have it just up on some green treated right now. I’d love to do something different than the green treated, but for now, this does fine.

Here are where I place the magnets too.

I probably wouldn’t have the magnets on there if my neighbors place wasn’t 25 feet from the smithy ![]()

Here is the horn. Just one that I’ll take off if I need to use the under side of the horn.

oh wow great suggestions!

i’ll try out that magnet trick.

My background is audio and damping walls, cabinets, and other things is commonplace. It seems that the same techniques that work there should work on an anvil. Look up damping materials, Dynamat and Sorbothane are 2 trade names and there are number of alternatives. Dynamat-type is an adhesive sheet with a compound like roofing tar with metal backing foil. Sorbothane-type is a urethane plastic usually used for grommets and feet but also sold in sheet form. A combination of the 2 applied to the anvil should attenuate the ringing but how much is unknown.

Hey Dusty - Welcome to the forums!

Do you use Dynamat at all? I was looking at the stuff some time ago just with putting up on a wall that is nearest to my neighbor.

I suppose I may need to apply it to the stud and have the wallboard attached over it? Thoughts on it?

I want to be noisier in my shop (read: power hammer) but it can be limiting with neighbors 25 feet away or so

Hello All,

All the previously mentioned methods should work to varying degrees.

Each anvil is unique in how it will react to being struck so if an anvil rings experimentation is the only way to determine what will quiet it. If using magnets move them around and try different sizes in different places.

One method I have had success with is to place several layers of asphalt shingles or tar paper under the ringing anvil between the stump/stand.

Jim

Small piece of rubber hose on the point of the horn. Try it, Really , rubber hose

Of course can’t forget my all time favorite, place anvil on a pile of dead cats. Works every time