Hello guys , my name is Barry Gardner a full time knifemaker in the Barossa Valley in South Australia www.gardnerknives.com , I’m wondering if anyone can help me , I’ve just bought a Hawkeye helve power hammer made in Cedar Rapids and stamped 1903 , I’m having trouble finding info ,any help would be great I’m looking forward to using it,any history on company or even anyone who owns one, cheers Baz and may you all have a safe and happy Christmas x

Hey Barry,

I don’t know much about the hammers - any shots of yours? I’d love to see it.

Any video or anything would be sweet too!

Barry,

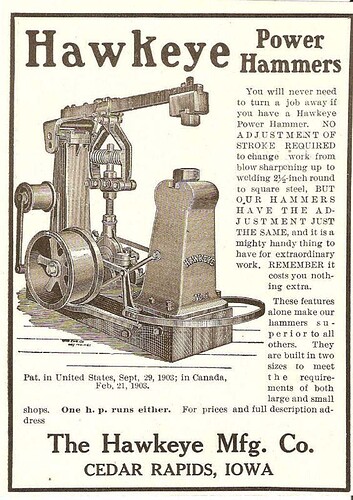

I have a #3 I have been restoring. The #3s are not as common as the #2s the main difference is the standard is made of wood in the #2. I have been researching “Hawkeye Manufacturing Co.” for several years and there isn’t a lot of info on them as they went out of business sometime after 1918. Yet I have been able to find some information on them. They also manufactured a Steam Engine Cylinder Wrench, Rope Making Machine and Three sizes of Single Cylinder Gas Pony Engines that were sold to Gade Mfg. co… Advertisements can be found in copies of American Blacksmith and the Blacksmith & Wheelwright. A Google search will turn up an electronic copy of Davidson & Strite’s Patent #739992 Hawkeye Yieldable Pitman for Power Hammer 1903. There is also a Canadian patent but as of yet I haven’t requested a copy from their patent office. There is also a chapter in the book Pounding Out the Profits by Freund yet some of his info is not always accurate. Hawkeye Mfg. Co. moved their factory at least 3 times (Tama, IA-Cedar Rapids, IA-Minneapolis, MN-Spooner, WI) I believe they did so to be closer to Cast Iron Foundries. There is some company historical background at smokstak.com/forum/showthread.php?t=51558 . I would like to get and or see some pictures of your hammer and I can help you with some technical info that I have come up with while researching and rebuilding my machine. Jim Bynum

I have a Hawkeye No3. Did you ever find an instruction manual on this hammer? I would like to put it in operation. Thanks, Rockforge

Hi Jimbo!

I have a Hawkeye number 2 stamped 1903, Just checking if anyone was able to find a manual or any info on this.

Thanks!

Carl

Hi Carl,

I haven’t found one, but I believe that something did exist at one time.

I have found references to a poster that identified all the parts of the hammer that was mailed to potential purchasers (if anyone knows of one that exists I’d like to know where it is at). I have some info that I have gleaned from the internet and old advertisements as follows:

Crude adjustments (thickness of material) were made by the threaded rod between the pitman and spring arms. fine adjustment was achieved by moving the pivot plate forward and back along the helve arm. The #2 is rated to work material up to 2-1/2" thick. The #2 should be run no faster than 300 strokes per minute (rpm). It was advertised that 1 horse power was all that was required to run all their hammers (keep in mind line shafts used different sized pulleys to gain mechanical advantage!). They are designed to run from an overhead line shaft driven with a slack belt. The power hammers drive pulley should turn in a counter clockwise direction when facing it.

Published quotes on adjustment:

All hammer sizes can be adjusted for special work. The iron block between plates on upper side of beam on #1 hammer can be used on either upper or lower side to raise or lower the head. The #2 and #3 have an adjustment in the connecting rod to raise or lower the head according to the nature of the work. The #3 has a special adjustment, the cap over the post at the rear end of striking beam can be raised and the lower holes used, the connecting rod screwed out of the eccentric an equal distance and locked in that position, when this is done the hammer will strike with full force and on the level when working extra heavy material.

The helve or striking beam enables the operator to strike as lightly as desired and with a little extra pressure of the foot a very powerful blow will result.

See U.S. Patent #739992 (google search)

I hope this info is helpful,

Happy Hammering!

JimboSmithy