Not really power hammer related, but the main purpose of the compressor will be to use it WITH a power hammer, so I’m posting it here! Can’t really justify another forum… Or maybe we do need one.

Anyways - I jumped on a compressor the other day that was too good of a deal to not go for.

The guy listed a 7.5 hp 2 stage 80 gallon Ingersroll Rand for $300, and his phone rang off the hook - price went up and I said I can be over there asap and we can work out a deal. After inspecting the pictures and talking to the guy as well, he said he doesn’t have 230 volt in his garage where it is, but he got it from his work when they were closing up shop and it was working then. They performed routine maintenance to it, and it was a “parting gift” to him as the shop got bought out.

Went to take a look at it, it looked in really good shape! They just cut the power cable, no big deal, oil through the sight glass seemed ok - a little low, maybe. Overall I was surprised with the condition it was in and got it for $450.

So! I now have a giant compressor out in the shop! I have a few other things I’ll be able to use it for, die grinder, paint sprayer, etc, but the main usage is that I plan on getting a pneumatic power hammer sometime in the future.

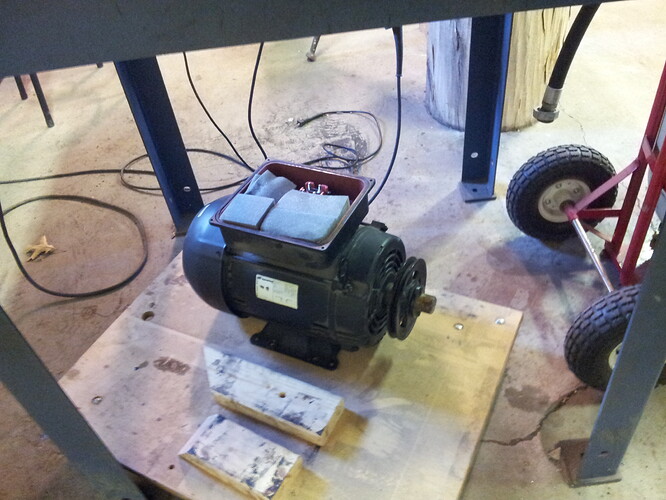

After wrestling it onto the trailer (500lb total weight), had a brief awkward situation with another buyer who arrived just after I was about to leaver, and I brought it home. Much easier to handle these things when you take off the motor and the pump itself - I was able to move it all myself when separating the parts.

I’m going to put new oil in it today and wire it up for 230 and plug it in. Hoping there isn’t anything majorly wrong with it, but given the shape, I have high hopes - anyways, very excited, and here are some photos of it!

Oh, and I did have one question of if that little device on the right side (bottom) of the compressor was an inline air drier? It looks like it has a little glass globe and release valve for when water gets in there, just am not completely positive. Still learning the parts.

Very excited ![]()