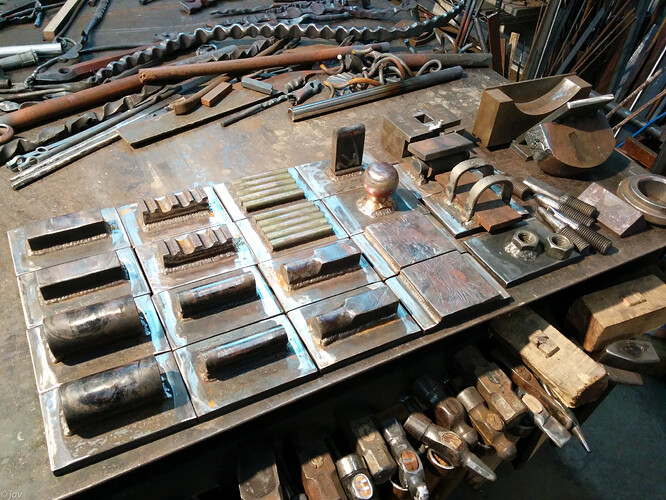

Thought I’d post a update to this post as it’s been a few years since the original post and I see lots of folks are still using it as a reference. The Press is still working like a champ. I find myself using it more than my power hammers as it’s quieter and doesn’t shake the entire neighborhood like the hammers do. I’ve made quite a few dies so far. They are generally easy to make or tweak. Most of the dies I make are mild steel. I do get some deforming on the dies but it’s pretty minimal. If you need higher heat resistant dies I’d suggest S7 or something similar for your dies. My punches are 4140, s7 or 1045

One thing I wish I would have added is a hole under the bottom ram where I could punch and pop slugs out of. I can get around this by using a built up bottom die but having the hole to allow deeper punching would be a nice feature.

I’m still around so if anyone wants more detail shots of the press or have any questions go ahead and ask them here (thats the whole point of this post).

Thank you so much for your excellent documentation of your hydraulic press build!

Can you tell me the total height of the “H” portion of your press and the thickness(s) of the top cap plate and bottom cap plate?

beat regards

Reg

Love all the info on this build, thank you. I’m looking to try to build one myself and am curious if I should do 25 ton or reduce to… say…15-16 tons? I’m just starting and want to dabble in Damascus so any advice would be appreciate. If 16tons, ous there any major pros or cons and any major changes to your design?

The press opens 10" Are you looking for the total height of the frame? (see picture). The top and bottom are way overkill at 1-1/4" solid thick pieces. I happened to have those sitting around so I thought it would be worthwhile to add them to cap off both ends. My thinking was 1. Cost to me…0$ 2. The more rigid I make the frame the more power I’ll be able to put into the forged piece. So in the end those are not required but it doesn’t hurt to have them either.

This is the only press I’ve ever used but…I have my doubts about 15-16 ton press for Damascus. Why…when I first built and ran my machine the hydraulic control valve (lever) was set to about 2/3 power. I’m guessing that brings me down into the range you are thinking about. It really felt underpowered. Making damascus requires high heat an pressure so the machine needs to be quick and powerful. Personally I’d hate to invest time and money into a machine that would maybe do the job. That all said I’m no damascus expert. I’d suggest going onto a blade smithing forum and asking around.

Good Luck,

Jeff

Thanks so much for your patience with my questions. Your press has “10 inches of travel” and you reference a cylinder from Surplus Center that has 8" of stroke. Please explain

With your press closed and no dies in place, do your platens touch?

Thank you kindly,

Reg

How many gallons is the gud tank, as Northern no longer offers this item. Do you have any problems with the fluid overheating?

Sent from my SM-S320VL using Tapatalk

I mistakenly measured it with the dies removed. So yes it does have 8" of travel.

t’s a 12 gallon tank. I think I have about 11 gallons in there. As for the tank and the fluid heating up. I ran the machine over an hour without stopping and when I was done I felt the side of the tank. It was warm to the touch but not concerning. Just guessing but maybe 150 degrees.

Javos,

I am just getting into the craft. Becoming medically disabled has gi ven me the time to invest in learning. I FULLY understand your coments on not wanting to disturb the wife (I actually schedule my “work time” around her needs for my help, so I mostly work at night.

I AM OVERLY ENVIOUS OF YOU]R WORK SPACE!!! I am barely squeezing into a 9’x12’ shed (tremendous heat levels, and no capability of a structurally capable floor to support a power hammer). Thus…I am extremely interested in your build, although (and please forgive any misinterpreted “downing”) I believe I would opt for slightly more tonnage…like 30"s. This “tonnage increase opt” would also apply to the person who asked in regards to a 15-17 ton being capable to set damascus/laminated welds. Your answer is 1M% correct…“high heat and presure”.

I did follow the aditional “how to” links you put in, but I would still love something of a “blueprint”/plans on your design. If you are willing, and can add them here, or through P.M. I would be forever in your debt.

Three questions though:

- what is the footprint of your press?

- what is the total height?

& - any versitility of running longer lines and connecting to a gas powdered pump? (As I said earlier…working in a tiny shed (but for me it is good as I spend MOST of my time in a chair, except moving said chair to another “station” and hammerin’ on the anvil…hence…running off a 115v extension cord and only using lights and 1 power tool at a time). Although a "back-up gen. would also solve some of that issue too, i guess! Lol

This press would have shaved hours off of me welding (4) 1/4x1 3/4x6 bars of 5160 by hand (all thanks and credit to J. Neilson for the how to on that…many “masters” told me to acoid it for a few years. J. gave me his process and enthusiastic encouragement…did it and a jellyroll of 5160/m4 bansaw blade body cuts, and mild shim stock by hand on my first try because of him).

Apologies for the ramble (no sleep due to medical issues and a bit more than “a little excited” from finding your W.I.P. post here.

At the bare minimum, THANK YOU for sharing! I wish more would follow suit.

Oh man, sorry I missed this post!

- what is the footprint of your press? > the table is 2’ x 3’

- what is the total height? > the height is just about 7’tall. I can kick myself but I had google sketch up plans for this and I lost them when my last external drive went belly up.

- any versitility of running longer lines and connecting to a gas powdered pump? I don’t see why this wouldn’t work. Log splitters work on this system and this is basically a vertical log splitter. That said… I’ve never tried that before, you may want to check with the professionals on that one.

Hope the build goes well!

Jeff-

Hi Jeff,

I’m nearing completion of my H-frame press and thankfully you offered this post. I refer to it often. I bought the Batson and McDaniels books but they leave a lot of questions. (My Batson book seems to have missing pages)

How did you torque your fittings, both (npt and npsm)? Torque values? Did you have any problems with leaks?

Thank you and kind regards,

Reg

Hej Javos !

I’m a French tool-blacksmith and I wanted to make my own vertical press, I draw my design and almost start to make it but when I started to make researches for the hydraulic parts in France they ask me for 4000€ (!!!) so it’s really too expensive for me, and then I found your press (nice design and work of yours) and the cost is more interesting for me, so I think I will order the parts from America (if possible). But in order to don’t make any returns if i’m wrong in the type/amount/size etc… of the parts, do you think you can tell me if you had to make any returns for your parts, any more advices maybe, so I can make the order (with the links you gave) and start the building, inspirated by your design (if you allow me of course). My work in France has just started this year (I was travelling through Europe to improve my skills for 3 years), and as I don’t have a striker, it would be easier with a press, i’m making axes and sharp tools for woodworking and fighting, hammers for work and common blacksmith order. Thank you for the work/share you did, sorry if I made mistakes in the writing, and have a nice day.

Best Regards,

PHB

Hey, I know this post is from a while back but I’d like to ask a couple questions if you’re around.

-whats the total length of the beams that make up the sides?

-the distance inside the two beams?

-how far are the dies apart at full open position?

-what size/thickness of plate did you use for the baseplates used when making dies?

I have the same size beam you’ve used and a lot of the other steels kicking around but I’d like some baseline measurements to get me started. Hope to hear from ya soon!

Great build by the way!!

Hydraulic machine is one of the best way to shaping the metal If anyone interested to buy any type of machinery the you can so with shaping machine.

that machine is incredible

Hello Javos,

I’m new here, but was thrilled to find your project. I wonder if you could post the specs for the cylinder? I’m not seeing anything other than a 5"? Rod diameter, stroke, etc would be great. I’m familiar with surplus center, the link you posted takes me to hydralulic cylinder spec- out page. I have been pondering this press build for a year or so, but was unsure how to proceed.

Thanks for your time and doing this for us!

Chad

Hey Jeff,

Scratch the question, I found it. For those wondering , Northern Tool offers a 5" inch bore cylinder in both an 8 “or 10” stroke, 2 " rod diameter, clevis ends. Only thing slowing me down now is I’m going to contact Concentric Rockford ( formerly Haldex), makers of the pumps on Jeff’s link. This to determine if my 5Hp, 3450 rpm motor will handle a 13.6 gpm pump. If not I’ll get the 11 gpm. It sounds like that’s plenty of pump for damascus if he’s punching 1"+ plate.

I will have an updated parts list for most of the ones Jeff kindly provided. Let me know if anyone needs it. Alternatively, Northern site will direct you to “similar” items when one is discontinued. Note some are NOT the same, the Prince control lever for example is available, but you need the ESA, not EDA model. One has a return to center spring, one does not.

Sorry Jeff, not trying to highjack your thread here!

No worries! I’m derelict at keeping up out here so I appreciate the updates and input.

-Jeff