Hi can you show a video of it operating please

tony862012@gmail.com.

Happy New Year

Visit @javosironworks on instagram. I have loads of videos out there of it running.

Hi everyone,

I’m completely new here and I realize that this is an old thread, but I would really like to build a similar press.

Could anyone give me the type, diameter and lengths of hydraulic pipes needed including the type and size of the hose fittings.

Unfortunately I need to order these online - no place near me where they could make it for me.

Needless to say - I need the exact lengths and reusable field fit hose fittings are too expensive.

Thanks,

Hi there! I would LOVE an updated parts list. Parting this out is driving me bonkers!!! Thank you!! -joshua

Hello, new to the blacksmithing and found your article.

Fantastic write up and I am in the process of building this press.

Reading the post you stated you had lost the original plans.

I think I may have found them on another forum.

I can’t upload the actual sketchup file. It won’t let me.

But here are some shots from it in jpeg form that it will allow me to upload.

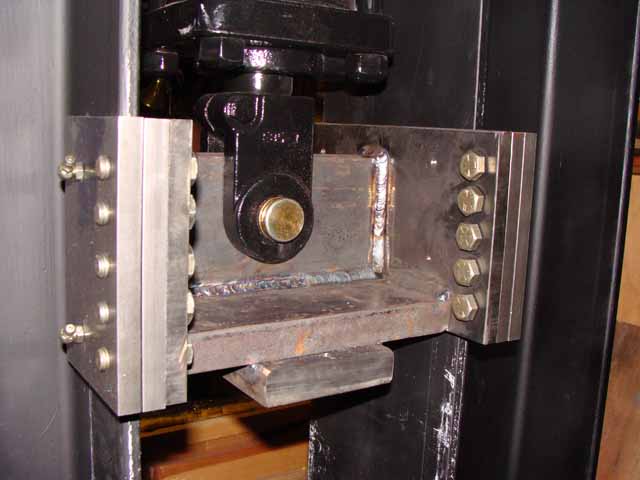

I also noticed you changed from the 8" wide flange to the 4" wide flange and this doesn’t show the change on the die holders, but other than that, I think they are identical.

I couldn’t find anything on the thickness of the steel plates or the angle iron sizes.

Hello All,

I have lost the parts list list I had. I have looked for it multiple times. Also, I’m in graduate school and have no time. I did buy the cylinder, a Lion 5" bore, 10 " stroke from surplus center and a 5 Hp Baldor motor 184T frame before ABB screwed them up. I have now acquired a lathe, vertical mill and surface grinder, an anvil and a heat treat furnace. I got bit by the machinist bug too. This is a disease! I also got delayed by having to put a new service panel for the whole house and a sub in garage. Spent summer fixing that. That was a PIA, flaky contractor. But it is permitted, finally.

I have been trying to get the machine tools up and running, when I can. I am also almost done with my forge. I am now considering building a press that will accommodate both the ram and an ratcheting style Dake or Famco arbor press on one frame ( perhaps the arbor mounted on the side with a daisy wheel. I don’t need 26 tons to press out a shaft, or bearings, etc.

I was originally able to find most of the parts , such as the pump, ( flex couplings, spiders called Lovejoy couplings) to connect motor to pump. A guy could buy a direct mount pump to fit your motor as well as reservoir tank, filter heads etc., at Northern tool. Unfortunately, a lot of their stuff is cheap chinese, so I shied away from the running parts. Space has become an issue so haven’t bitten into it , yet.

As far as the hydraulics: I am a little imitated by that one. There is a good hydraulic outfit in town that could steer me in a safe direction. You must have a relief in the spool valve so overpressure can return to tank. These type of pumps are dumb and will work their guts out til they overheat oil and detonate or catch fire.Thus, I believe a high quality open center hi-lo pump, like for a log splitter is the way to go. As I mentioned, there are good hydraulic shops out there, JFrost- Once you get your frame built, you can get the hoses made to length. You won’t know the exact lengths until you build it and have your components. Once you do, you could make a drawing and send it to a shop if need be. BTW, They are not cheap.

Hope that helped a little. When I can get to it, I will post all the info. Zigzzg, thanks for the drawings. I will try to add some pics I have of Javos’s. I have some more, but don’t want to have them sent in a Google Drive link or whatever due to file size.

Sorry I haven’t been active here guys, life got in the way of what I want to do…

Hi, really grateful for your post!

This may be a dumb question, but can you tell me if the extra headspace is completely necessary? For instance, could the top section of I-beam in the center be removed and the sides shortened to match and then maybe just reinforce with a 1" top plate or something like that? Could the same be done to the bottom? Could I hypothetically cut out the bottom and weld the base of the beams to a 1" base plate and then fix the dyes directly to that?

If reinforced properly with a top and bottom plate, could this work? Would it still have sufficient structural integrity?

I ask because I am seriously limited on space and height and I estimate doing this could potentially reduce the height by 12-14" overall.

Was there plans for this press? If its not to big of a deal id appreciate it, as i am trying to build one of my one